Do you need jumbo bags for transporting or storing your products? If so, the following six points you should consider first.

Jumbo bags are also known as Ton bag, FIBC bag, Big Jumbo, Bulk bag, and so forth. The qualities of the bag are also varying according to user requirements. It is hard to choose what type and quality ton bags you need for your business. For deciding the perfect jumbo bags for storing and transporting your products, the following 6 points will help you.

You should consider the size, load-bearing capacity, used raw materials, types, available models, and their particular use areas before choosing the bags.

1. The size of Jumbo bags

The Jumbo bags come with a variety of size options. The average-sized Jumbo bag is usually 90 to 200 cm in height and 90 to 120 cm in width. You can get a custom size Jumbo bag according to your specified requirement. The total weight of a Jumbo bag is about 3 to 6 pounds, and it can carry one to several tons of materials. Again, these vary according to the purpose through several customizations. There is no standard size of jumbo bags even. The most popular size of the Jumbo bag is the one-ton capacity variant which is 90X90X90 cm. You can find all possible sizes and volumes of Jumbo bags in the following link.

It is hard to picture the size of the Jumbo bags without looking at them practically. A material-full bag standing on a standard size pallet is about waist to chest height of an average height person. The following link may help you to understand it better. It contains a picture of a one-ton bag with two women standing next to the bags.

2. Types of Jumbo bags

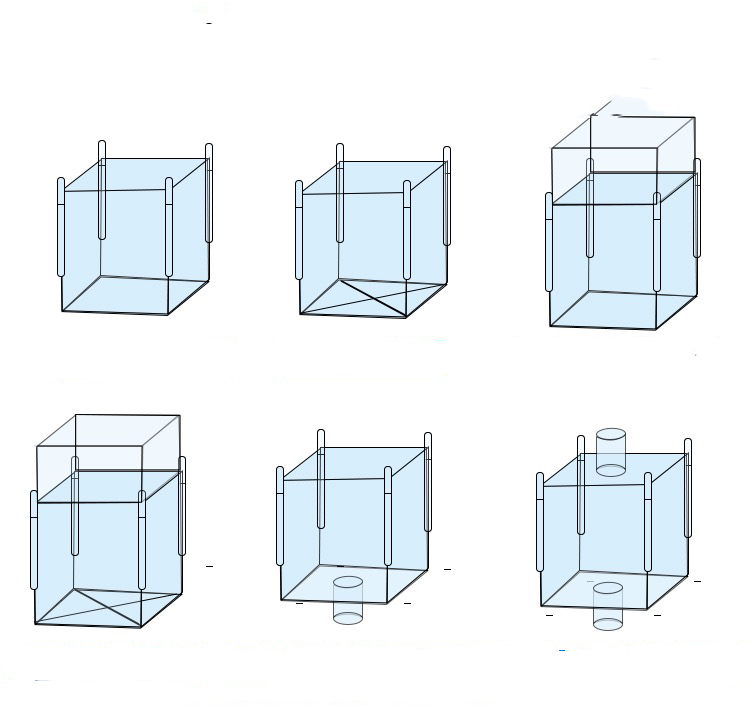

The jumbo bags are available in different shapes like circular, U-panel, four-panel, baffle, and more.

- Circular bag; Tubular woven fabrics are used to make this type of bag. Tubular fabric is manufactured as a tube and does not need any side seam. This type of bag cannot retain its shape while holding materials in it. When products load in them, depending on the type of the material, it changes its appearance. You can compare it to a big tomato when fully loaded.

- U-panel bag; This is better than circular-shaped bags. Two U-shaped woven panels joined together to make this type of bag. It can hold its cube shape much better than the circular bags while loaded.

- Four-Panel bag; The four-panel bag is the standard option for getting a square shape when loaded with materials. Four pieces of woven PP fabric joined together to make the sides of the container. A separate square-shaped panel use for making the bottom of the bags.

- Baffle bag; If cube-shaped packaging is required then, this is the most suitable option. Here four additional baffles are sewn at the four sides of the bags. So, it can maintain the cubic shape regardless of the material type loaded in it.

3. The load-bearing capacity of Jumbo bags

The capacity of Jumbo bags indicates how much materials they can hold and carry. The Jumbo bags are superior in offering the highest product to package weight than any other packaging container. The capacity often describes as cubic feet or cubic meters. You can calculate the volume of a bag by multiplying the length, width, and height. However, the bulge also needs to consider while calculating the size of the bags. When you fill the bags with materials, due to the load of the materials, it stretches. As a result, an increase in capacity. That is why manufacturers advertise a little more as the capacity of the bag.

What about the weight capacity of the Jumbo bags? The materials type you want to carry with the bags is also a crucial factor. A heavy-weight material must affect the volumetric range of the bags. If you load low-density materials, you can load them over, and if you carry high-density stuff, you must fill them low.

4. Materials used for making Jumbo bags

The Jumbo bags are produced from plastic woven fabric. The raw material of that woven fabric is a soft thermoplastic material named polypropylene. For better protection and extra durability, PVC use sometimes. A refurbished Jumbo bag is a good option nowadays to choose from convention one. They are cost-effective, durable, lightweight, and as well as sturdy. Refurbished jumbo bags are environmentally friendly. These bags minimize the plastic landfill and help our globe to stay calm and fertile.

5. Style available/ Models of Jumbo bags

Jumbo bags are available in different styles for a particular use. Jumbo bags can be categorized according to diverse lifting options, filling options, and discharging options.

- Lifting option: The lifting option of jumbo bags can be any one of the following four.

- Four corner loops; It has four loops at each side of the bags to carry

- Loop extenders; It is suitable for long transportation and has extra grip and support.

- Sleeve lifts; It contains two sleeves. Carrying instruments can be inserted in these sleeves to transport more securely.

- Stevedore; This option is also for ease of transportation

- Filling option: The filling options are also several types.

- Entire open top; The top is fully open

- Fill Spout; A top spout is attached so that powder and granular materials can be loaded effortlessly.

- Dome top; this option is suitable for filling sensitive materials.

- Duffel top; This option is the modified version of the complete open form. It prevents unwanted exposure of goods during transportation.

- Discharge option: As the jumbo bags are heavy and it is also tough to discharge materials from them. The jumbo bags are also available with suitable discharge options.

- Plain bottom: No discharge option from the bottom

- Spout discharge: A spout placed at the bottom of the bags can be closed or opened when required.

- Dome bottom: Dome shape discharge option, suitable for powder materials.

6. Where the Jumbo bag use

Jumbo bags use in several sectors involving but not limited to the following;

- Agriculture: Jumbo bags use for transporting grain, feed, seeds, and other agricultural goods with the suitability of storing and preservation options. Food-grade bags woven bags are perfect for transporting human and animal consumable products.

- Construction: Cement, sand, bricks, lumber, gravel, and a ton of other construction materials are often requiring long-term storing or long-distance transportation, and here the jumbo bags play their role with reliability and confidence.

- Food processing: The jumbo bags hugely use in the food processing industry for the food item and raw-materials transporting and storing as jumbo bags are available with facilities like chemical-free and food-grade.

- Mining: For transporting valuable materials from mine to the processing industry, no other than jumbo bags perform the task perfectly. It allows overloading, secure transporting without rupture, convenient handling, and a lot more.

- Pharmaceutical: Jumbo bags are also an excellent option for pharmaceutical product transporting and storing because these bags are available in chemical-free facilities.

Jumbo bags customize further for getting the exact requirement of storing and transporting sensitive products. That is why jumbo bags are also available with facilities like outer or inner coating, extra inner layer, air-proof, dissipative, ventilated, conductive, and so forth.